| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ANSHAN ANZHONG MINING MACHINERY CO., LTD

No.294 Anqian Road, Gaoxin District, Anshan, Liaoning, 114051 / / / CHINA

|

Contact Info: +86 152 4210 2697

|

Hall: 6

Stand: 618-08

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Anzhong Inc. Pioneering the Future of Vibrating&Crushing Industry Established in 1994 Vertical setup including vibrating screen,feeder,crusher in China Products and Services Specializes in the production of Vibrating Screens, Feeders, Crushers,Asphalt mixing plants,etc..Offers comprehensive solutions for screening and crushing needs in the coal, metallurgy, mining and road construction machinery industries. Innovation and Excellence More than 140 national patents held across our product range. Developer and drafter of 25 industry standards in China s vibrating screen machinery sector. Quality and Compliance All equipment complies with international standards including CE, EAC, ISO9001, ISO14001, and ISO45001. Global Reach Extensive market presence in over 20 countries including Germany,the USA, Australia, Chile, Peru,Saudi Arabia, and notably Turkey. Trusted by industry giants such as BHP in Chile and JSW Company in India. State-of-the-Art Facilities Production area spans 130,000 square meters equipped with the most advanced machining and manufacturing equipment sourced from Germany, the USA, Japan, and Taiwan Province. Commitment to the Environment Dedicated to sustainable practices with advanced environmental management systems. Customer Focused Tailored solutions to meet specific mining and screening challenges. Responsive customer service and robust support network. Visit us at Booth #618/08,Hall 6 Experience innovation and reliability with Anzhong!

Applications: High performance large horizontal linear vibrating screen is mainly used for classification and dewatering operations after SAG Mill, ball milling and HPRG in major mines and ore dressing plants, as well as tailing dry discharge operations, and also for dewatering, demedium and desliming operations of medium coal, clean coal, gangue and raw coal in coal washing plants. ★ The vibration parameters of the screen have reached the international advanced level: double amplitude 2A=9-11mm; Vibrating frequency n=850-900r/min; The vibration intensity reaches 4.5g-5g; High screening efficiency and large capacity compared to the previous year. ★ The lower cross beam of the screen surface, the support beam of the screen panel, the rear baffle plate, the side panel, and the reinforced parts on the side panel are made of specific high-strength panels, with the yield strength greater than 350Mpa. ★ The forced synchronous box vibrator driven by helical gear which has the advantages of stable and reliable operation, low noise, stable projectile angle, constant speed material movement, uniform material layer thickness and no local accumulation; ★ The bearing adopts the special bearing for vibration machinery (SKF or FAG brand), and its lubrication method adopts splash lubrication of thin oil gear. The formation of oil mist makes the oil film on the surface of bearing rolling body uniform and fully lubricated, and the bearing is not easy to heat up and has long service life. ★ The material contact part below the screen surface is designed with tight wear-resistant and anticorrosion rubber treatment (imported rubber panel with original packaging from Germany), improving the service life by 2-3 times. ★ The whole assembly of screen frame adopts cold riveting technology (ring-groove rivet connection) to avoid uneven assembly stress and loose vibration; The reinforced parts on the side panel adopts steel panel bending parts to ensure its mechanical properties; The mounting main beam of vibrator adopts low carbon steel double l-shaped structure, which is planed and groove welded to form, with strong impact resistance, bending resistance and good manufacturability. The lower beam of screen frame adopts rectangular square beam structure, which has high strength, large bending section coefficient, small bending moment and long comprehensive mechanical life under the same conditions.

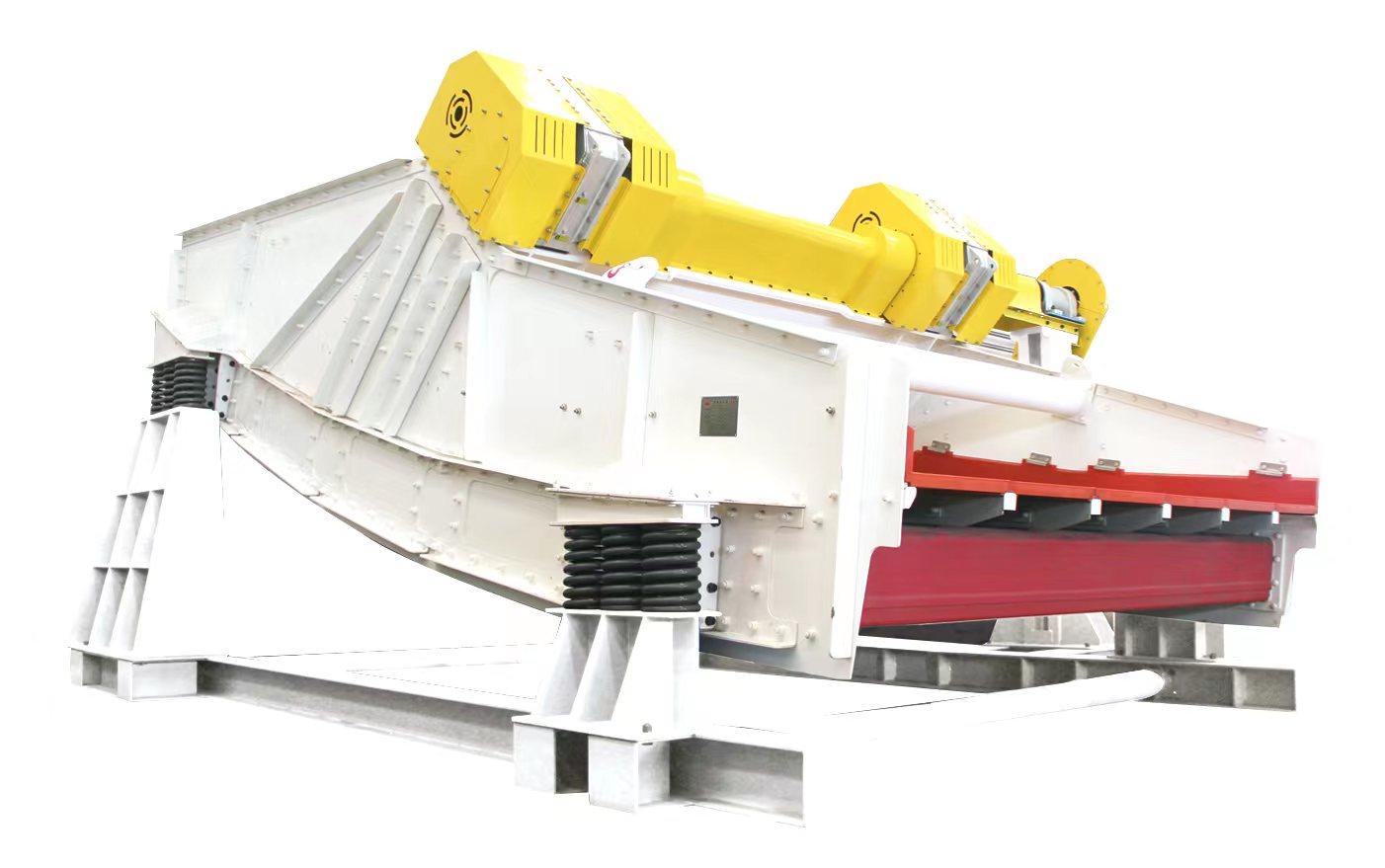

Applications: It is used for dewatering, de-medium and desliming of materials, and also for classification of material particle size. It is suitable for screening operations with a large amount of undersize materials (>60%). Product features: The principle is to inject the multi-stage dip angle for screen surface on the basis of the horizontal screen surface of the linear vibrating screen. A larger inclined screen surface is designed at the feeding end of the screen, and then it descends step by step at a certain number of angles until it reach-es the discharge outlet, so that the overall screen surface is concave arc shape similar to that of the fruit banana,so that the whole screen surface is concave arc, and its shape is similar to that of fruit bananas The principle is to inject the multi-stage dip angle for screen surface on the basis of the horizontal screen surface of the linear vibrating screen. A larger inclined screen surface is designed at the feeding end of the screen,and then t descends step by step at a certain number of angles until it reaches the discharge outlet so that the overall screen surface is concave arc shape similar to that of the fruit banana,so that the whole screen surface is concave arc, and its shape similar to that of fruit bananas. The material moves at different speeds and projectile strengths on each stage screen surface to meet the needs of different particle sizes thorough passing through the screen. The large and small particles on the screen surface are loose and layered obviously. The large materials pass through the steep slope of the feeding screen stage quickly, and the small materials settle rapidly. This early layering makes the fine particles close to the screen surface faster, and can pass through the screen aperture gap relatively unimpeded, and become the undersize material.Therefore, the capacity of the banana screen is 1.2-1.5 times higher than that of the conventional screen. The concave arc multi-stage screen surface, with long effective screen surface and decreasing dip angle of each screen surface in turn. It has the principle of equal thickness screening, large capacity and high screening efficiency. Driven by one set motor, two box-type vibrators are installed on the supporting main beam of the screen frame, the helical gear is forced to drive, the bearing is lubricated by thin oil splashing, the rigidity is high, the projectile angle is stable, the operation is reliable and the failure rate is low. Large capacity per unit area and high screening efficiency.(Width 2.4-4.9m). The company is the earliest manufacturer of banana screen in China.Its banana screen is rated as special,refined, special and new product at the provincial level,and also listed as the national key new product;At present, the products have been applied to more than 1000 sets in coal,mining and other industries.At , the largest production model is ZXT4985. The company divides banana screens into two types: for classification and for dewatering,de-medium and desliming. The number of screen surface stages is 5-7,the classifying angle is 10-35°and the classifying speed is 0.45-3m/s; De-medium angle:5-25°,De-medium speed:0.35-1.7m/s.The vibration direction angle is 45°,the vibrating frequency is 900r/min, the amplitude is 10-11mm, and the vibration strength is 4.5-5g.

Applications: YAO circular vibrating screen is mainly used for particle size classification of loose materials, and is widely used in coal, metallurgy, mining, sand aggregate.etc.. Based on the traditional circular screen technology, our company has developed a new generation of high-efficiency circular screen. YAO circular screen has the ad vantages of large capacity, high screening efficiency, thin oil lubrication of the vibrator without oil leakage, long bearing life and high reliability of the screen frame. YAO circular vibrating screen has a double-shaft form, driven end synchronous belt forced synchronization, and screen width is above 3.0m. The vibration parameters of the screen have reached the international advanced level: double am plitude 2A=9-12mm; Vibrating frequency n= 730-850r/min; The vibration intensity reaches 3.Sg-4.Sg; High screening efficiency and large capacity compared to the previous year; The vibrator is the combined vibrator with eccentric shaft and eccentric block. It is installed on the screen frame through the shaft guard tube and arranged in two groups in parallel. The structure is firm and at the same time, and can enhance the rigidity of the screen frame; The bearing arrangement of the screen is equal and the exciting force is large; Strong bearing capacity. The bearing is lubricated by thin oil, and the oil film is fully lubricated, with relatively long service life and convenient maintenance. The sealing method adopts labyrinth, rubber seal and conical face combination seal, which makes the oil seal more tight. The vibrator is installed and arranged in a scientific position and fixed on the center of gravity posi tion of the screen box. The screen runs smoothly. The motion track at each point is a positive circle. The material moves at a uniform speed on the screen su rface. The overall force of the screen frame is unifo rm. The principle of two shafts forced synchronization ensures stable and reliable operation . The motion track of the amplitude at each point of the screen is completely consistent. The material runs at a uniform speed and has a high thorough screening rate. The support structure of the upper and lower layer screen panels of the screen frame adopts the integral bracket, which makes the overall rigidity of the screen frame stronger, impact resistant, and large supporting capacity to meet the requirements of large capacity, large particle size materials, and heavy load operation . Vibrators are arranged between the upper and lower layer screen panels. The space is spacious (500-800mm), which is convenient for vibrator maintenance and screen mesh replacement.

Applications: Single shaft circular vibrating screen is mainly used for pre-screening and inspection screening of ore crushing closed circuit screening processes in major mines and mineral processing plants. It is also used for particle size classification of sand and stone aggregates, as well as for raw coal particle size classifi cation operations in coal washing plants. The screen surface width is :2.4m. Product features: The vibration parameters of the screen have reached the international advanced level: double amplitude 2A=9-12mm; Vibrating frequency n= 730-850r/min; The vibration intensity reaches 3.Sg-4.Sg; High screening efficiency and large capacity compared to the previous year; The vibrator is the combined vibrator with eccentric shaft and eccentric block. It is installed on the screen frame through the shaft guard tube and arranged in two groups in parallel. The structure is firm and at the same time, and can enhance the rigidity of the screen frame; The bearing arrangement of the screen is equal and the exciting force is large; Strong bearing ca pacity. The bearing is lubricated by thin oil, and the oil film is fully lubricated, with relatively long ser vice life and convenient maintenance. The sealing method adopts labyrinth, rubber seal and conical face combination seal, which makes the oil seal more tight. The vibrator is installed and arranged in a scientific position and fixed on the center of gravity position of the screen box. The screen runs smoot hly . The motion track at each point is a posi tive circle. The material moves at a uniform speed on the screen surface . The overall force of the screen frame is unifo rm. The principle of two shafts forced synchronization ensures stable and reliable operation . The motion track of the amplitude at each point of the screen is completely consistent. The material runs at a uniform speed and has a high thorough screening rate. The support structure of the upper and lower layer screen panels of the screen frame adopts the integral bracket, which makes the overall rigidity of the screen frame stronger, impact resis tant, and large supporting capacity to meet the requirements of large capacity, large particle size materials, and heavy load operation . Vibrators are arranged between the upper and lower layer screen panels. The space is spacious (500-800mm), which is convenient for vibrator maintenance and screen mesh replacement.

Applications: According to the vibration trajectory, the relaxation screen is divided into circular vibration trajectory re laxation screen and linear vibration trajectory relaxation sieve. It is mainly used for particle size classifica tion of various medium and fine particles and powder materials. The industry grading problems of sticky holes and stuck holes can also achieve the ideal screening effect for the screening of viscous and wet fine particle coal (3-13mm, water content 7-14%). Flip-flop is divided into the circular flip-flop and linear flip-flop according to the vibration track. It is mainly used for particle size classification of various medium and fine particles and powder materials. The classification particle size is 3-25mm, which solves the classification problem of materials with sticky openings and stuck openings, and can also achieve ideal screening results for screening of sticky and wet fine particle coai (3-13mm, water content 7-14%). Product features: The main machine vibrates under low vibration intensity, and the screen surface and materials run under high projection intensity (the projection acceleration of the material is 30 to 50 times the acceleration of gravity). The material particles have a high jumping stroke, are loose and di vided quickly, and are thoroughly screened, which reduces the inertial force of the machine body s operation, greatly extending the service life of the screen machine, and achieving high efficiency and energy saving. The screen openings of the screen panel can produce slight deformation with the relaxation movement, which can effectively overcome the phenomenon of stuck openings and blocked openings in the material. It has a self-cleaning function . The unit area of the screen machine has high screening efficiency and large processing capa city. The screen panel is made of high-elastic polyurethane material, which is wear-resistant and tensile-resistant, with a high opening rate. The fixing method does not require bolts, and it is easy to disassemble and replace. The whole screen frame is assembled by cold riveting technology (ring groove rivet connection) to avoid uneven assembly stress and vibration loosening; the main body of the side plate is made of high-strength plate to ensure its mechanical propert ies.The vibrator bearing is lubricated with thin oil, which is fully lubricated and long service life, the lower cross beam of the screen frame adopts anisotropic rectangular beam, which has high reliability .

Applications GPS series linear vibrating screen is mainly suitable for dewatering of coal slime or tailings, and is widely used in coal preparation plants, mineral processing plants, sand and stone aggregates and other industries. It has the characteristics of advanced structure, high vibrating frequency, large capacity, good dewatering effect, convenient maintenance, firmness and durability. Product features: The vibrator can adopt three stru ct ures : gear forced vibrator, self synchronous vibrator, and vibrat ing motor. Rotating speed 15OOrpm, double amplitude 3.5-4.5mm.The vibration intensity is>Sg, which has the advantages of good dewatering effect and high vibrationin intensity. The cross beam under the screen adopts the rectangular beam structure with high structural strength. Sticking rubber can be selected to prevent materials from corroding the cross beam, in creasing its service life by 2-3 times The overall assembly of the screen frame adopts the riveted structure to avoid uneven assembly stress and vibration looseness, with high structural strength. The screen panel can be used modular polyurethane or stainless steel, with the advantages of high opening rate and good dewatering effect.

Application: High-frequency vibrating fine screen is an ideal screening equipment to realize wet classification, dewatering, demedium, secondary pulping and material cleaning of medium and fine-grained miner als and fine powder materials in mineral processing plants. It is widely used in industries such as min eral processing, coal preparation, minera The screening machine is l processing, chemical raw materials and food processing. Product features:divided into single screen and single channel, single screen and multiple chan nels, and multiple screens superimposed with multiple channels for feeding. The screening machine is driven by a vibration motor, which is light in weight, reliable in operation, low in noise and requires little maintenance The motion trajectory is a straight line The vibration frequency is 20 Hz~ SOHz; the amplitude is 0.5 ~ 3mm The installation inclination angle ofthe screen surface is in the range of -5° to 25° , which is deter mined according to the screening requirements of different materials It can be equipped with polyurethane fine mesh, which has high opening rate, wear resistance, and does not block holes. It can also be equipped with stainless steel wire woven fine composite mesh Multi-screen superimposed multi-channel feeding high-frequency screen increases the production capacity of the system and achieves the maximum screening capacity and work efficiency with the smallest floor space, the simplest system pipeline connection, and the lowest engineering cost and operating cost.

Applications GZT vibrating feeder screening machine is a kind of vibrating feeder screening equipment. This equipment is mainly used in mining, metallurgy, coal, and other industries to feed the crusher after pre-sc reening. Generally, it is installed under the material bin, and it can carry the load and start. The equipment has reasonable structure, large bearing capacity, strong impact resistance, stable and reliable operation, and convenient installation and maintenance Product features The vibrator is an eccentric block vibrator, which is directly installed on the double I-beam. It has a solid structure and can enhance the rigidity ofthe screen frame. The screen bearings are evenly ar ranged, with large exciting force and strong load-bearing capacity. The eccentric block of the vibra tor is forcibly synchronized through the gear, the movement is smooth and reliable, and the material runs at a uniform speed. The bearing lubrication adopts rare lubrication, the oil film is fully lubricated, the service life is relatively long, and maintenance is convenient. The sealing method adopts skeleton oil seal and rubber gasket seal. The plates are rolled from Ansteel. The shape cutting and positioning holes ofthe steel plate are completed by high-precision CNC cutting machines to ensure the accuracy ofthe shape and drilling position. Reinforcing ribs or protective plates are reasonably arranged in the areas where the side plates are subject to greater stress to effectively increase the strength of the side plates. The upper part ofthe screen frame is an I-beam, and the lower part is a double I-beam, which makes the overall rigidity ofthe screen frame stronger, impact-resistant, and has a large material holding capacity. It can be started with material load to meet the needs of large particle size and large processing capacity The position of the vibrator is scientifically arranged and fixed at the back and lower part of the screen box. The position here has high stiffness and the material comes from top to bottom. The vibrator vibrates from bottom to front, which is very reasonable. The drive device uses a motor to reduce speed through a V-belt and a pulley, and then through the driver, using a universal drive shaft to directly connect to the vibrator. The V-belt protects the motor, and then decelerates through the pulley to select the optimal speed. Through the direct connection between the driver and the universal shaft, when starting and stopping, due to the nature of the cardan shaft, it will not be affected by excessive vibration during starting and stopping.

Applications It is widely used in metal and non-metal minerals, cement, sand and gravel, metallurgy and other industries. It is an ideal crushing equipment suitable for medium and fine crushing of various ores and rocks with Platt hardness below 16. It is widely used in crushing operations of various types of high hardness and high abrasion resistance ores. Product features Transmission gear Large and small spiral bevel gears can achieve high torque and high energy efficiency transmission. Adjustable eccentricity The combination of the eccentric copper sleeve and the eccentric sleeve can easily achieve multiple eccentricity settings by installing keys in different keyways of the eccentric copper sleeve to adapt to the requirements of different ores and working conditions, thereby achieving materials to be packed into the material bin for feeding and optimizing the particle size curve of crushing product and production capacity Curved crushing cavity According to the principle of material laminated crushing and the wear characteristics of the cavity wall, the cavity shape is designed as a curve, so that the crusher has the advantages of large output, high product quality, and low wear cost. Overload protection system Through hydraulic and electrical protection, the main machine is protected to minimize damage to the host during overload. Auto Run automatic control system It realizes functions such as overload protection, over-iron protection, automatic compensation for liner wear, etc., and maximizes the effectiveness of the crusher by filling the bin with materials. Reliable hydraulic lubrication system The lubrication system and hydraulic system are modularly designed and operate independently. By interlocking with the main motor, the oil temperature, flow, pressure, power, and abnormal power supply are monitored to protect the main machine.

PEC SERIES JAW CRUSHER Applications Jaw crusher is suitable for crushing various types of ores, shale, coal and other materials . Widely used in mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and other fields. It can meet the most demanding coarse crushing operation requirements economically, conveniently and safely Product features: High capacity, large crushing ratio, low wear and large feed size. The deep-cavity symmetrical crushing chamber design of the jaw crusher maximizes the feed size, capacity and crushing ratio of the crusher. The design of the motion mechanism combined with the crusher s operating speed enables the crusher to achieve greater output and lower jaw plate wear. The ideal crushing angle ensures the materials are crushed and passed smoothly, making the crushing ratio larger. Reliable heavy-duty movable jaw assembly The movable jaw is made of high-quality cast steel and is driven by a large cast pulley and fly wheel. The forged heavy-duty eccentric shaft and high-quality large-scale spherical roller bearings made of SKF or FAG make the crusher extremely reliable. The head of the movable jaw is equipped with a replaceable guard plate to effectively protect the movable jaw from the impact of the feed. Solid body structure The body frame is composed of a cast steel fixed jaw at the front end, rolled steel plates on both sides and a cast steel adjusting seat at the rear. All butt welds are used to improve the stress of the steel plates. After the frame is assembled and welded, it is overall annealed to make the frame high strength, durable and simple in structure Wedge outlet adjustment system The mechanical or hydraulic wedge outlet adjustment system is simpler and safer than the gasket adjustment system. Symmetrical crushing cavity Symmetrical crushing cavity design improves crushing efficiency. Installation method without anchor bolts The good balance performance allows the crusher to be installed without anchor bolts. The normal operation ofthe crusher can be achieved through the rubber damping blocks installed on the bottom and sides ofthe crusher support, which can slow down vibration impacts and avoid damage to the foundation. Integrated motor installation The motor support is integrated with the crusher, which reduces the installation space of the crusher and the length of the V-belt, making it simple to use and extending the service life of the V-belt. It can also be equipped with standard pulley covers and flywheel covers. Centralized lubrication system for easy maintenance. The eccentric shaft can be lubricated manually or equipped with an automatic lubrication device (optional) Easy installation for convenient transportation The crusher can be easily transported in different ways according to different transportation requirements (such as underground installation or weight and space restrictions) The flywheel/moving jaw can be transported separately, as a whole, or even as the frame is disassembled.

No represented companies found.

The company has no registered brand information.

TR

TR