| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KET-MAK ARITMA TESİSİ İMALAT VE PAZARLAMA TİCARET A.Ş.

İstanbul Mermerciler San. Sit. 32. Sok. No: 11 Köseler Köyü / Dilovası / KOCAELİ / TÜRKİYE

|

Contact Info: +90 262 728 1375

|

Hall: 7

Stand: 716

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

KETMAK Inc., established in 1997 by Engineer A. Levent KETENCI, manufactures machinery and equipment utilized for mineral enrichment and treatment & recycling of the waste water of all kinds of mining industries such as gold, copper, silver, chromium, magnesite, marble, granite, ceramics, aggregate, sand, coal, feldspar, etc. KETMAK, whose goal is always continuous development without abandoning its principles in line with its vision since establishment, has become a pioneer, particularly in mining sector. KETMAK has added to its portfolio over 700 organizations in domestic and abroad with its successful projects in the field of mineral beneficiation and industrial waste water treatment & recycling systems starting with the marble industry. Today, the plants installed by KETMAK in 40 different countries of the world continue to operate successfully. KETPOL Inc. was founded under KETMAK Group Companies in 2011 to provide logistics support to the plants installed by KETMAK. Ketpol serves in the field of treatment chemicals and filter clothes which have vital roles in treatment systems.

Filter presses are the oldest method of sludge dewatering. Filter presses have become the most common equipment used in treatment and mineral enrichment plants thanks to their ability to produce a cake close to dry, their practical use, automatic discharge mechanisms and their applicability to different processes. Filter press sizes we produce - 630x630 - 800x800 - 1000x1000 - 1500x1500 - 2000x2000 (mm) Filter press types (according to plate type) - Chamber - Membrane - Mix-pack (Chamber+Membrane) Optional Features - Drip Tray - Automatic Cloth Washing System - Cake Washing (Reverse Washing) - Automatic Air Blowing (Cake Drying/Core Blow)

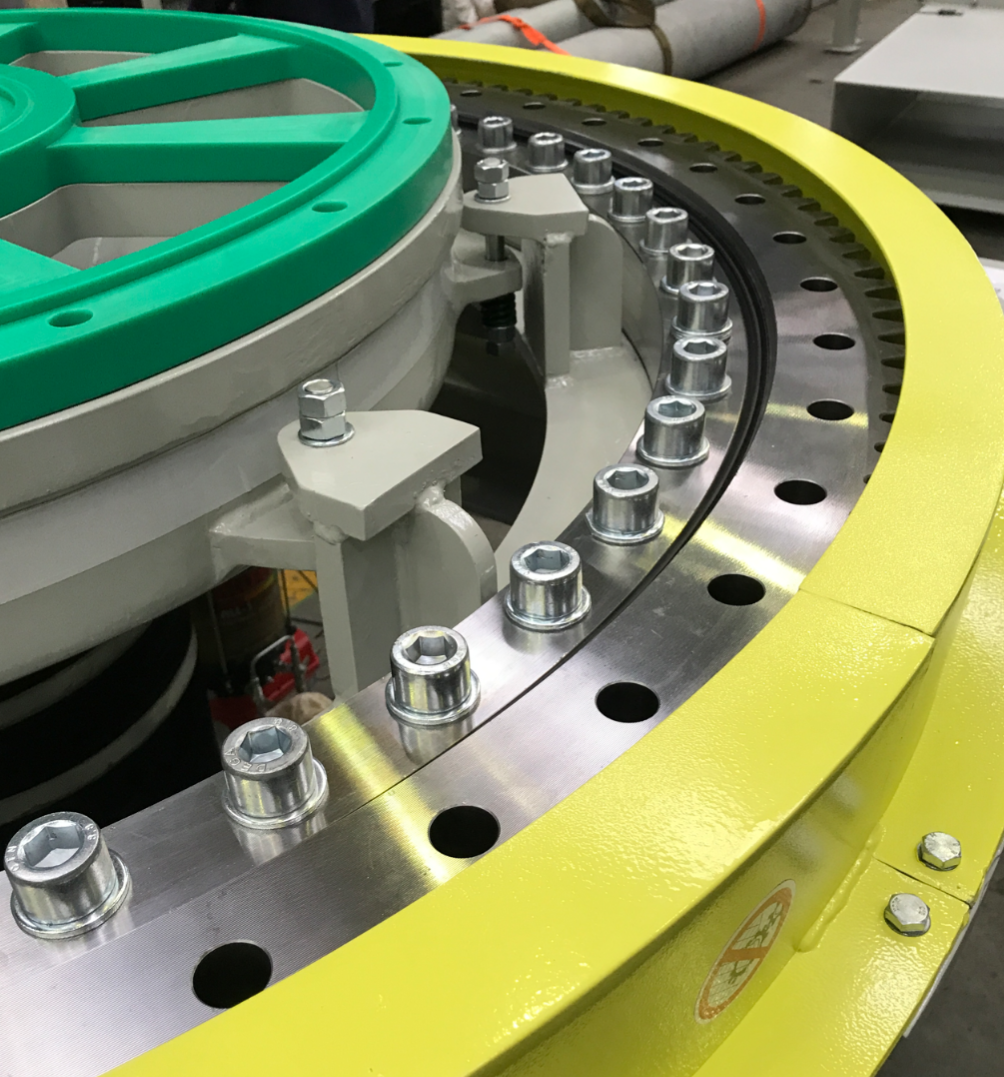

Thickener is a cylindrical plant (pool) with large diameter in which just the colloidal particles remain as a result of settling of suspended solids important portion in the slurry and which provides turning back of water to the process by effusing the partial treated water from whole circle. Moreover, scraping wings at the decayed bottom transport large particles to the central part and so seperately disposal of that sediment is provided. Condensing units produced by us provide the increase of solid materials in the sludge by taking of some portion of water and by this means the sludge becomes to be able to filtrated. Thickeners decrease the total sludge amount substantially and to do so they decrease the dimensions of treatment plants. We have tank productions with various diameters and heights according to the patterns of behavior (characteristics) of the sludge. Elevation at scraping wings is obtainable up to 500 mm by the special reducers which are our own production. Sludge is discharged from the tank only in desired density as deciding the sludge density by means of special automation program (software).

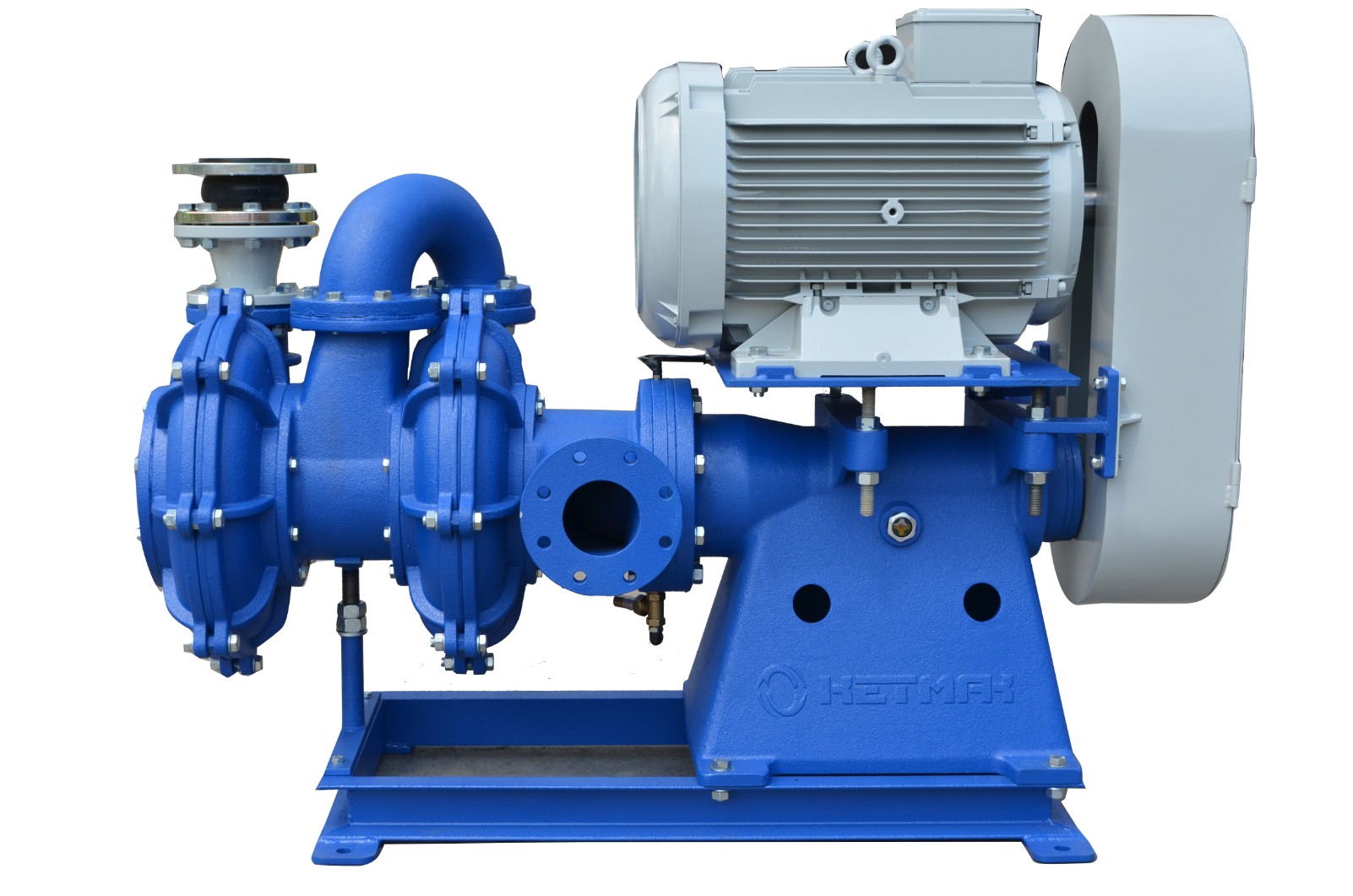

KYN - 5000 Producer KETMAK Model KYN 5000 Motor 13/17 KW Cooling Type Water cooling Exit Pressure 6 bar Flowrate 85 m3/h Impeller Size Ø226 mm Protection Class IP 55 Entrance Size DN100 PN6 Exit Size DN80 PN6 Body Material GG 22 Inner Lining Rubber 65-70 Shor Impeller Material AISI 4140 Weight 180 kg Driving System Direct Electricity Feding 380V, 50 Hz, 28A Revolution 1500-3000 rpm Sealing Type Mechanical Seal (Tuc-Tuc) KYN - 6000 Producer KETMAK Model KYN 6000 Motor 15 KW Cooling Type Water cooling Exit Pressure 6 bar Flowrate 75 m3/h Impeller Size Ø226 mm Protection Class IP 55 Entrance Size DN100 PN6 Exit Size DN80 PN6 Body Material GG 22 Inner Lining Rubber 65-70 Shor Impeller Material AISI 4140 Weight 190 kg Driving System Pulley drive Electricity Feding 380V, 50 Hz, 24A Motor Revolution 1450 rpm Pump Revolution 2200 rpm Sealing Type Mechanical Seal (Tuc-Tuc)

Double Staged Turbo Slurry Pump Producer KETMAK Model TP902 Motor Revolution 1450 rpm Pump Revolution 1950 rpm Pressure (max) 12 bar Flowrate 115 m3/h Sealing Type Mechanical Seal (Tuc-Tuc) Cooling Type Water Cooling Power 37 Kw Protection Class IP 55 Electricity Feding 380V, 50 Hz, 60A Entrance Size DN100 PN16 Exit Size DN80 PN16 Body Material GG 22 Impeller Material AISI 4140 Impeller Size Ø290 mm (2 pcs) Inner Lining Rubber 65-70 Shor Weight 780 Kg Driving Type Pulley drive Single Staged Turbo Slurry Pump Producer KETMAK Model TP901 Motor Revolution 1450 rpm Pump Revolution 1950 rpm Pressure 7 bar Flowrate 115 m3/h Sealing Type Mechanical Seal (Tuc-Tuc) Cooling Type Water Cooling Power 22 Kw Protection Class IP 65 Electricity Feding 380V, 50 Hz, 26A Entrance Size DN100 PN16 Exit Size DN80 PN6 Body Material GG22 Impeller Material AISI 4140 Impeller Size Ø290 mm Inner Lining Rubber 65-70 Shor Weight 610 Kg Driving Type Pulley drive

Company Name KETMAK Piston Diameter 350 mm Number of Pistons 2 Max. Hydraulic Pressure 250 Bar Max. Mud Pressure 16 Bar Max. Flow Rate 90 m3/h Electric Power 18.5 kW Feeding 380 V, 50 Hz Protection Class IP 55 Hydraulic Oil Tank 400 litres Cooling Method With water Conversion Rate 1/17

Application Fields Pumping of domestic and industrial raw wastewater Wastewater treatment plants Pumping of rain water Drainage and releasing works Brand KETMAK Model BERG 40 BERG 50 BERG 75 Capacity 15 m 270 m³/h 15 m 390 m³/h 15 m 450 m³/h Power 40 Hp 50 Hp 75 Hp Impeller Diameter 290 mm 305 mm 340 mm Exit Diameter DN 150 / PN 6 Power Consumption 30 kW, 50Hz 37 kW, 50Hz 55 kW, 50Hz Hull Material GG 22 Protection Class IP 55 Revolution 1450 d/d Current 380V, 48A

Compact Treatment is a machine designed for small-scale facilities. All machinery and equipment needed for treatment are built in to machine; Drainage Pump Sedimentation Tank Pneumatic Actuator Dosing Unit Dosing Pump Clean Water Tank Sludge Tank and Mixer Slurry Pump (Filterpress Feeding Pump) Filter Press We manufacture two types of Ket-Compact with capacities 800 lt/min and 1200 lt/min. Can easily be assembled in 4 hours Easy to transport Minimum space need

Brand KETMAK Model PN 470 Feeding 100m3 /h slurry (%25 solid) Vacum Pressure 1 bar Vaccum Power 90kW Revolution Driver adjustable Lubrication Timed greasing Control System Omron touchscreen Electrical Power 100Kw Protection Class IP65 Feeding 380V, 50Hz Electric Equipment Telemekanik, Omron Entrance Size Dn100, Pn100 Hull Material St37

Polyelectrolyte used as flocculant is used commonly in drinking water and waste water treatment. Polyelectrolyte can be supplied as dry or liquid. Dry (powder) polyelectrolyte must be made into solution prior to use. This unit which is designed to provide ease of operation operates fully automatically together with storage part. Our dosing units are composed of three divisions with different stirring speeds, by means of this flocculant solution becomes ideal for use. Solution concentration in the unit, whose capacity is in the range of 500 lt/h - 10.000 lt/h, can be adjusted from 0,05% to 0,5%.

Reverse osmosis system which is used as a kind of advanced filtration method is mainly the process of removing anion and cation ions in the water. High pressure pumps are used for reverse osmosis systems. Pressurized water is delivered to membranes and by means of that process, water becomes purified. Reverse osmosis systems can be classified as: Tap water reverse osmosis systems Brackish water reverse osmosis systems Sea water reverse osmosis systems Mobile reverse osmosis systems Application Fields: Water bottling plants Irrigation and greenhouse Textile factories Quarries City drinking water facilities Hotel, camping and schools Boiler feed water preparation Water recovery systems Other industrial processes

No represented companies found.

The company has no registered brand information.

TR

TR