| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KÖRFEZ DÖKÜM SANAYİ VE TİCARET ANONİM ŞİRKETİ

DOSB 2. Kısım D2033 Sok. No: 2, 41455 Dilovas / / KOCAELİ / TÜRKİYE

|

Contact Info: +90 262 754 5177

|

Hall: 6

Stand: 608

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Korfez Foundry creates effective business solutions for the cement and mining industry. Its main operation area is alloyed steel castings, with a focus on heat, wear, and impact-resistant steel castings. Our products are generated and delivered based on customer drawings and specifications, with additional operations such as machining, surface treatment, and assembly. We export 90% of our products to more than 80 countries on six continents. We have over 44,000 patterns in our archive. We are capable of generating products with unit weights between 0.5 and 8,000 kgs. We can produce 800 tons monthly. Korfez Foundry currently operates at Dilovası, Kocaeli, Turkey factory, with a total area of 40.000m2 and a covered area of 18.000m2. We are in over 80 countries on six continents and export 90% of our products for various businesses. Our main areas of expertise are in the following alloys Plain Carbon steels, Low, medium, and high alloy steels, High Chromium/ High Nickel heat-resistant steels, High Chromium and Ni-Hard type abrasive resistant steels, High Manganese impact-resistant steel, High alloy cast iron grades, Bi-Metallic Castings. Our high-quality and custom-based solutions for the industries Hammer Crusher Roller Crusher Impact Crusher Jaw Crusher Cone Crusher Tube Mill Vertical Mill Hammer Mill Roller Mill Kiln Cooler Pre-Heater Incinerator Boiler

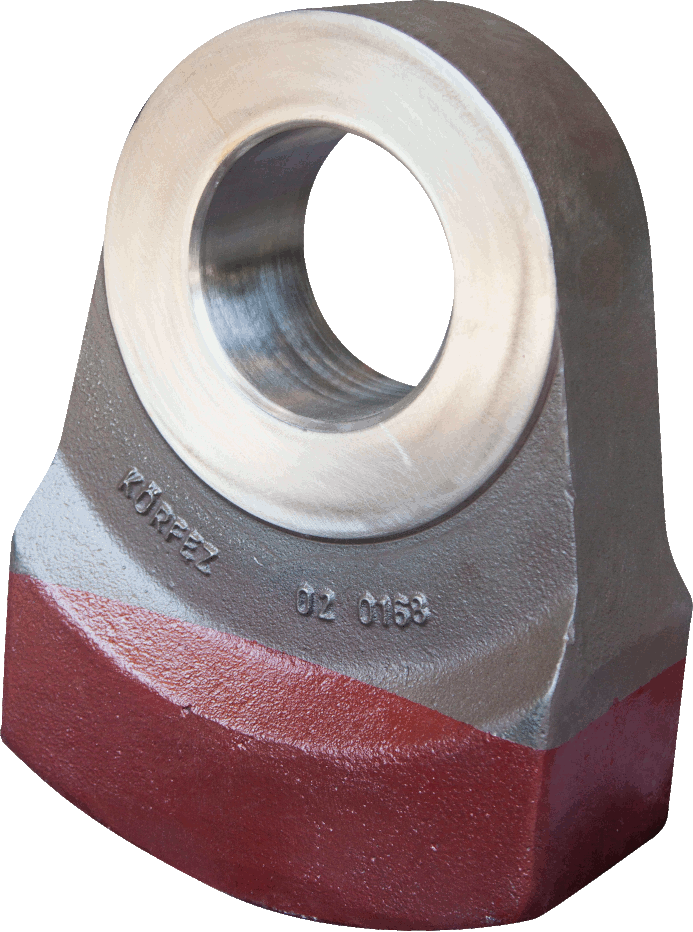

Korfez Foundry provides a wide range of wear solutions for your hammer crushers. KORFEZ can offer Bi-Metallic, Ceramic Composite, Selective Hardened, Cr-based or Manganese-based conventional hammers. Our engineers are dedicated to finding the most effective solution for your systems.

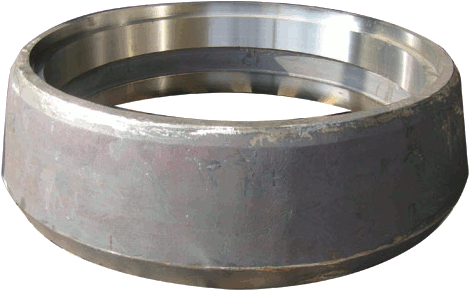

Korfez Foundry provides a wide range of wear solutions for your roller crushers. Our engineers can offer alternative materials for your roller crusher parts. Design improvements and special surface applications makes KORFEZ different than an ordinary jobbing foundry. Our engineers are dedicated to finding the most effective solution for your system.

Korfez Foundry provides a wide range of wear solutions for your impact crushers. We do not only deliver the highest quality impact bars, but also other wearing accessories and services to improve the service life of your crusher based on consultation with our engineers.

Korfez Foundry provides a wide range of wear solutions for your cone crushers. Due to our flexible production line we are able to produce cone crushers of between a few kgs to 8 tons. Our diverse inhouse heavy machining shop allows us to reach the tightest tolerances.

Korfez Foundry produces various wear and impact resistant parts for your vertical mill, such as roller tire, segmented rollers, table liners and nozzle rings. Besides suitable material selections we offer ceramic composite reinforced components and other special applications to deliver the highest performance with a minimized risk of breakage. Korfez Foundry can produce grinding rollers of up to 8.000 kgs and delivers them finish machined and ready for assembly. To facilitate and speed up the assembly on site (and consequently save man-hours) the components of the roller segments and table segments are marked with numbers showing their position in the final assembly.

Korfez Foundry provides wide range of wear solutions for your hammer mills. Our expertise in wear behavior in grinding systems enables us to offer the most suitable materials and designs for your milling hammers casings, rotors and various accessories. KORFEZ can offer Bi-Metallic, Ceramic Composite, Selective Hardened, Cr-based or Manganese-based conventional hammers. Our engineers are dedicated to finding the most effective solution for your systems.

Korfez Foundry provides a wide range of kiln parts. Korfez Foundry also offers spare parts and can provide complete sets like kiln inlet/outlet segments, kiln chutes, doors and accessories. For parts delivered as a set, the elements are preassembled in our plant before delivery to assure trouble-free assembly on site. Through design improvements and the selection of suitable materials we can improve performance and service life.

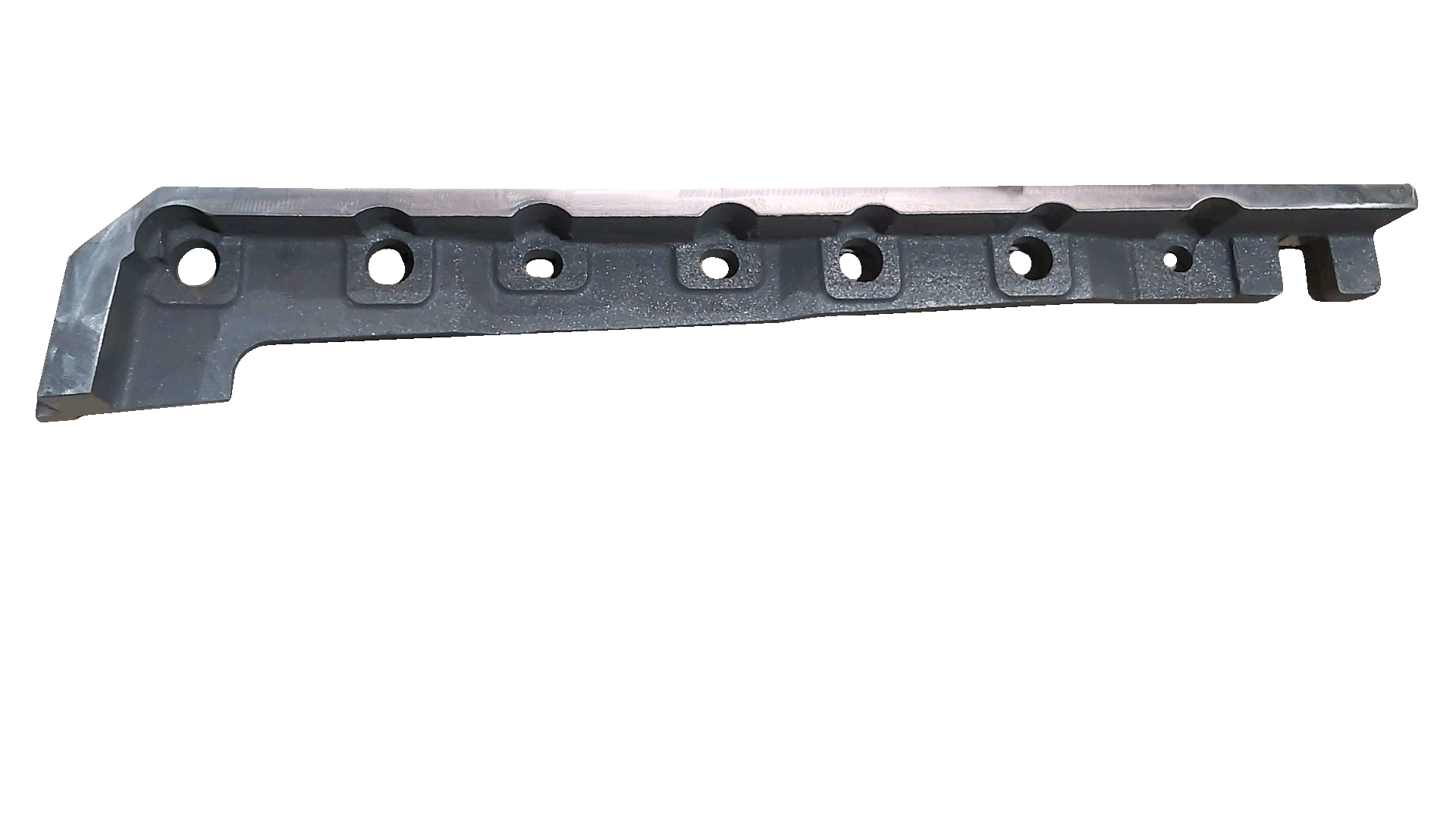

Korfez Foundry has been producing parts for coolers since the start of the company. Following technological developments Korfez Foundry has garnered considerable experience in cooler parts. Due to many years of working in the same field, our knowledge comprises a variety of early wet or semi wet systems to plate coolers and new generation coolers. Our specifically designed production line is capable of producing even the most difficult geometries with the highest precision with our engineers dedicated to finding the most suitable solution for your cooler.

Korfez Foundry has a complex production facility for sand castings, centrifugal casting, welding, machining and assembling that is able to offer the best solutions that fulfill the technical requirements of even the most complicated boiler parts.

Korfez Foundry offers the highest-quality incinerator parts. Our specifically designed production line is capable of producing even the most difficult geometries with the highest precision. KORFEZ can also easily fulfill the strictest criteria for production of incinerator grates.

No represented companies found.

The company has no registered brand information.

TR

TR